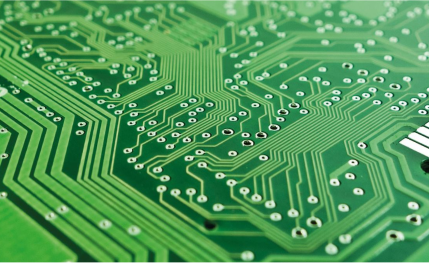

Product Name

PCBA

86% of manufacturers find quality inspection challenging due to the high cycle time and high cost of installation

PROBLEM STATEMENT

The circuit boards have to be inspected for all the correct components mounted with correct polarity at its location without damages. Solder quality also plays an important role for Post wave THT inspection. Defect on boards would result in short circuit or incompatibility issues after assembly.

LINCODE SOLUTION

Using a static inspection method, visual inspection is carried out on the stem bracket to inspect for presence of holes, presence of chamfer and OCR.

Automated inspection is achieved by LIVIS with

remarkable accuracy of 91.7% with only 50-60 images.

HOW IT WORKS ?

TECHNICAL SPECIFICATIONS

Area Covered:

370mm X 370mm

Implementation:

Workstation

Efficiency Increased:

91.7%

Defect Size:

5mm

Camera Resolution:

1 mp webcam

OCR Match:

Yes

Cycle Time:

2.9ms

No Of Parameters to check:

3

© 2022 Lincode - All Rights Reserved.