Origin Story

Before building LIVIS, Lincode visited over 500 factories to understand their specific manufacturing challenges. Over 80% reported quality inspection as the #1 challenge impacting operational efficiency. Defects slipped through. Good parts got scrapped. Labor was working overtime. After building and testing various models to address these challenges in real factory environments, LIVIS was born.

Since its founding, Lincode has conducted over 260M+ inspections, trained on 800M+ datasets, developed 700+ pre-trained AI models, raised over $9M from investors, and expanded to 14+ countries.

Key Features and Benefits:

Unparalleled Accuracy

Increase the efficiency of traditional vision systems with LIVIS by improving reliability of inspection results and reducing false calls.

Expanded Capabilities

Supercharge legacy camera systems with LIVIS by expanding their native capabilities for quality inspection to include advanced defect detection, assembly verification, and label inspection.

Data Traceability

Capture images, inspection results, timestamps, and unique identifiers to comply with regulations and track data during production processes and beyond.

Hardware Agnostic

Connect LIVIS to existing cameras and factory control systems to improve quality inspection without expensive hardware upgrades or major process changes.

No-Code AI Platform

Train and deploy Lincode’s proprietary AI models for new parts, defects, and production lines using a simple, no-code interface.

Curated Datasets

Go live with new use cases in under a day by leveraging Lincode’s pre-trained AI models and industry-specific datasets for a wide range of manufacturing processes and materials.

Centralized Management

Manage workstations and data from production lines across the globe, whether deploying LIVIS on fixed camera stations, conveyers, robotic arms, or mobile devices.

Analytics & Reporting

Analyze inspection results to track performance and improve manufacturing processes, first pass yield, throughput, and overall equipment effectiveness.

Inspections

Datatsets

Pre-Trained AI models

Countries

Why Lincode ?

Traditional Machine Vision

Limitations of traditional machine vision require factories to set up secondary manual inspections that create bottlenecks in production.

Traditional machine vision systems generally have limited functionality, require controlled environments, and produce a high rate of false calls. These limitations stem from the “golden image” approach to model training where any variance from a particular control set is deemed defective. But many manufacturing requirements allow certain variances too complex for machine vision systems to understand, leading to bottlenecks in production.

Other AI Platforms

AI Platforms lead with promises of efficiency but result in long training cycles and pilot purgatory due to lack of available datasets.

Lincode Intelligent Visual Inspection System (LIVIS)

AI Platforms lead with promises of efficiency but result in long training cycles and pilot purgatory due to lack of available datasets.

LIVIS is a true deep learning system built for manufacturing. The system includes proprietary AI models trained on industry- and use case- specific datasets, enabling manufacturers to deploy significantly faster than with other AI platforms. Unbound by rule-based structures, LIVIS gets smarter over time by learning which variances are acceptable and which are not. As a result, LIVIS consistently outperforms traditional machine vision technology and other AI platforms in accuracy, latency, and speed.

The Lincode Difference

+1Traditional Machine Vision SystemsSub-heading goes here. |

+1Other AI PlatformsSub-heading goes here. |

+4LIVIS SuiteSub-heading goes here. |

|

|---|---|---|---|

Feature 1Sub-heading goes here. |

Text/text |

Text/text |

Text/text |

Feature 2Sub-heading goes here. |

Text/text |

Text/text |

Text/text |

Feature 3Sub-heading goes here. |

Text/text |

Text/text |

Text/text |

Feature 4Sub-heading goes here. |

|||

Feature 5Sub-heading goes here. |

|||

Feature 6Sub-heading goes here. |

|||

Feature 7Sub-heading goes here. |

|||

Our Team

Our Partners

Lincode works with various partners, including system integrators, solution partners, and resellers to provide LIVIS to clients worldwide. Contact sales@lincode.ai to learn more.

Testimonials

We have been using Lincode’s AI-based solution in our facility for the last 3 years and have observed a drastic improvement in performance:

- Inspection cycle time reduced from over 60 seconds to just 5 seconds per unit.

- False call rate reduced from approximately 30% to less than 3%, greatly improving accuracy and process reliability.

The ease of programming and flexibility of the system are the features we value most. Engineers can easily set up and teach the system using just a few sample images, eliminating the need for time-consuming programming typically required in rule-based systems. This makes the system highly adaptable and user-friendly.

Compared to other inspection systems, Lincode’s LIVIS system delivers lower false call rates and much better adaptability to product-specific needs. It is by far the best solution we have used for customized inspection requirements across a variety of products.

Siraj Puthanpurayil, Senior General Manager Manufacturing Technology, Global Supply Chain

Schneider Electric

Since we started using the Lincode inspection system, we’ve had a significant increase in productivity. The system can detect defects in the bolt no matter how the part is placed, along with missing pins. This has reduced our manual efforts and increased operator efficiency. We are very satisfied with the system and will certainly work with Lincode on other projects.

Andreas Nußmüller, Managing Director

Nußmüller Montagetechnik

As pioneers in visual quality inspection using AI, Lincode has helped us solve many challenges in BIW automation lines where traditional vision systems fail to support our applications. The Lincode team is highly flexible to our requirements and has extended their services beyond the initial specifications to help solve the problems on-site.

Rajsekhar Jaypal, AVP, Welding Systems

DiFACTO Robotics and Automation

Awards

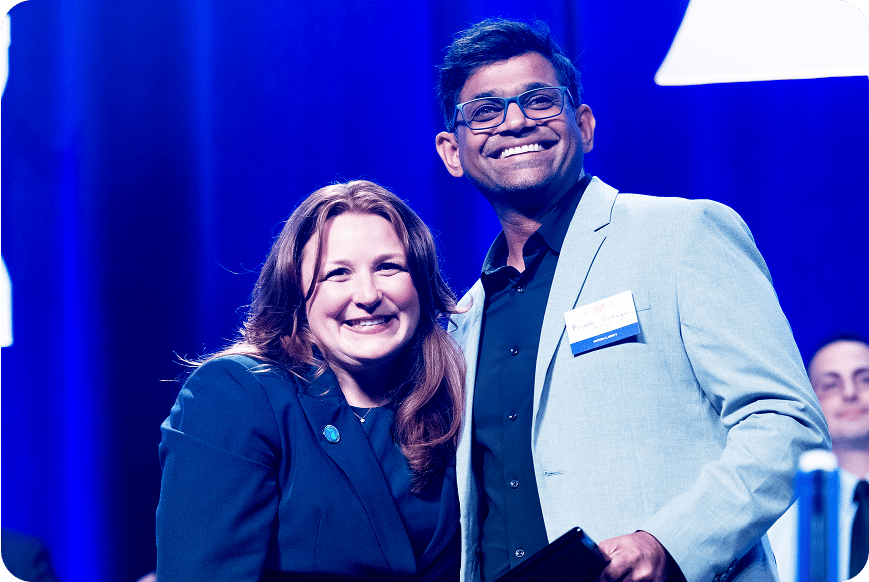

Michigan government presents Lincode CEO, Rajesh Iyengar, with the 2024 Best Small Business Award at the Michigan Celebrates Small Business Summit on May 21, 2024

Michigan Celebrates Small Business

Best Small Business Award 2024

Centrepolis Accelerator

Best Manufacturing Technology 2024

Advanced Manufacturing Expo

Pitch Competition Winner 2023

Careers

We are a collection of passionate and innovative engineers and business professionals united by a common purpose - to build better AI products for the manufacturing sector. We value creativity, collaboration, hard work, and integrity. If you are looking to challenge yourself and join a talented team, check out our available positions. We’d love to hear from you.

Internship Program

Lincode's 6-month internship program is the perfect way to gain the skills and experience you need to launch a successful career in data science, software development, or AI. During your internship, you'll work on cutting-edge projects while working closely with experienced professionals who will help you develop critical skills and knowledge. Enjoy competitive stipends, perks, certificates, and a potential pathway to full-time employment based on outstanding performance.

)%20(3)-1.png?width=1063&height=537&name=Green%20Facebook%20Group%20Hello%20Welcome%20Post%20(%D0%94%D0%BE%D0%BF%D0%B8%D1%81%20%D0%B2%20Instagram%20(45))%20(3)-1.png)