Lincode Intelligent Visual Inspection System - LIVIS

AI-Powered Visual Inspection

No-Code Platform

Data-Driven Insights

Capture

Annotate

Train

Deploy

Improve

LIVIS Suite

Our flagship product, Lincode Intelligent Visual Inspection System (LIVIS), enables manufacturers to train and deploy AI models for surface defect detection and assembly verification with a simple, no-code platform. LIVIS is compatible with most camera systems, supports on-premise or cloud deployments, and seamlessly integrates with existing factory environments.

Edge+

Edge+

Edge-based computer vision controller that runs AI inspections and inferencing

- Conducts real-time visual inspections of components, assemblies, and packaging

- Improves the accuracy and capabilities of traditional machine vision systems

- Deploys on-premise in client-controlled environments

Insights

Insights

Intuitive platform to manage Edge+ controllers and multiple workstations

- No-code interface to train new parts and defects

- Update inspection parameters and track key metrics

- Reduce time to value and total cost of ownership of inspection systems

Platform

Platform

Advanced analytics and reporting of critical manufacturing metrics

- Track parts, defects, and unique identifiers

- Perform root cause analysis, supplier grading, and preventative maintenance

- Improve first pass yield, throughput, and overall equipment effectiveness

Lincode Intelligent Visual Inspection System (LIVIS) is a proprietary Al-based visual inspection system for quality control. LIVIS empowers manufacturers and supply chain partners to supercharge quality inspection operations by improving reliability, expanding capabilities, simplifying data training, and automating analytics and reports. Whether deploying a new inspection station or integrating with existing cameras, LIVIS makes visual inspection faster, more accurate, and highly scalable.

-

LIVIS Platform. Lincode’s proprietary Al model training and inspection workstation management platform. Using a simple no-code interface, factory managers and operators can quickly train custom inspection recipes (Al Inspectors) to fit their production needs. LIVIS Platform connects with multiple LIVIS Edge+ applications to deploy these AI Inspectors and create quality inspection workflows.

-

LIVIS Edge+. Lincode’s proprietary runtime software that conducts real-time quality inspections of parts in production. Leveraging manufacturing-specific machine learning models, LIVIS Edge+ performs Al inferencing directly at the edge. The system easily integrates with industrial cameras and factory automation systems, enabling rapid deployment across production lines.

Core Competencies

Surface Defect Detection

Identify and classify surface defects, foreign objects & debris, and other defects reliably in real factory conditions.

Assembly Verification

Verify the presence/absence, orientation, and alignment of components to ensure proper assembly.

Anomaly Detection

Catch untrained anomalies with unsupervised learning models to spot new issues when they first occur.

Our Products

Every LIVIS system includes two components: LIVIS Platform and LIVIS Edge+.

Platform

Platform

No-code platform to train and deploy AI models for new parts, defects, and production lines

-

Intuitive development interface to manage workstations, update inspection parameters, and track key metrics

-

Secure platform to aggregate and manage data from multiple production lines and factories

-

Reduce time to value and total cost of ownership of inspection systems

-

Pre-Trained AI models

-

Auto-Annotate Datasets

-

Store Data On-Prem or Cloud

-

Fast Deployments

AI InspectorTM

Recipe Builder

Continuous Learning

Train and deploy proprietary, industry-specific AI models using 30-50 images (avg).

Create and deploy customized inspection workflows to conduct visual inspections using AI inspections.

LIVIS is a true deep learning platform. The more inspections you run, the more smarter it becomes.

Edge+

Edge+

Advanced edge-based software solution designed to transform industrial inspections with speed, accuracy, and expanded capabilities

-

Provides the runtime environment for LIVIS AI models to conduct real-time visual inspections without reliance on cloud latency

-

Improves the accuracy and capabilities of traditional machine vision systems with advanced AI

-

Run advanced analytics for data traceability, root cause analysis, and predictive maintenance.

-

Unparalleled Accuracy

-

Expand Inspection Capabilities

-

Hardware Agnostic

-

Seamless Integration

Operator Panel

Controller

Hardware & Software Integration

LIVIS includes a user-friendly panel for operators to run inspections and generate reports. The panel is fully customizable by clients and system integrators.

Plug and play edge controller (computer) to deploy the runtime software on-premise in client-controlled environments.

LIVIS connects to existing camera and lighting systems for easy installation. LIVIS also integrates with ERP, MES, PLC and other industrial control systems.

Evolution of Visual Inspection

.webp?width=76&height=75&name=Group%20(28).webp)

Traditional Machine Vision

Traditional Machine Vision systems generally have limited functionality, rely on controlled environments, and often produce high rates of false calls. These limitations are a function of "rule-based" systems, where any deviation from a control set may be marked defective. However, many manufacturing parameters permit certain variances or operate in dynamic environments, rendering traditional systems unreliable and causing bottlenecks in production and quality control.

Standard AI Platforms

Standard AI Platforms have overcome many limitations of rule-based systems but require extensive datasets to produce reliable results. The lack of available data covering the range of parts, defects, and production environments often leaves manufacturers in pilot purgatory. Resolving these issues often requires significant investment and machine downtime.

Is Different

Is Different

LIVIS is a true deep learning platform, unbound by rule-based systems. LIVIS gets smarter over time and learns which variances are acceptable and which are not. LIVIS also comes with pre-trained models built on custom industry- and use case- specific datasets, enabling manufacturers to deploy significantly faster than with other AI platforms. As a result, LIVIS consistently outperforms traditional machine vision technology and other AI platforms in accuracy, latency, and speed.

Key Features and Benefits:

Unparalleled Accuracy

Increase the efficiency of traditional vision systems with LIVIS by improving reliability of inspection results and reducing false calls.

Expanded Capabilities

Supercharge legacy camera systems with LIVIS by expanding their native capabilities for quality inspection to include advanced defect detection, assembly verification, and label inspection.

Data Traceability

Capture images, inspection results, timestamps, and unique identifiers to comply with regulations and track data during production processes and beyond.

Hardware Agnostic

Connect LIVIS to existing cameras and factory control systems to improve quality inspection without expensive hardware upgrades or major process changes.

No-Code AI Platform

Train and deploy Lincode’s proprietary AI models for new parts, defects, and production lines using a simple, no-code interface.

Curated Datasets

Go live with new use cases in under a day by leveraging Lincode’s pre-trained AI models and industry-specific datasets for a wide range of manufacturing processes and materials.

Centralized Management

Manage workstations and data from production lines across the globe, whether deploying LIVIS on fixed camera stations, conveyers, robotic arms, or mobile devices.

Analytics & Reporting

Analyze inspection results to track performance and improve manufacturing processes, first pass yield, throughput, and overall equipment effectiveness.

Industries

Automotive

Aerospace & Defense

Electronics

Semiconductor

Printing & Packaging

Food & Beverage

.png?width=800&height=634&name=image%20(5).png)

PCBA inspection

- Check for solder inspection, solder bridge, improper solder

- Identify missing components

- Ensure proper component placement for polarity

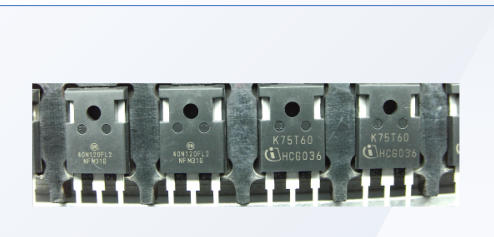

IGBT inspection

- Verify sequence position for array of components

- Check for presence of thermostat

- Validate vendor matching component

UPS inspection

- Identify Surface defects like scratches, dents

- Validate presence of fastener

- Verify alignment of cable connection

Piston Inspection

- Check for the presence/absence of pins

- Track the number of pins

- Defect analysis such as, scratches, porosity, black spot

- Color analysis

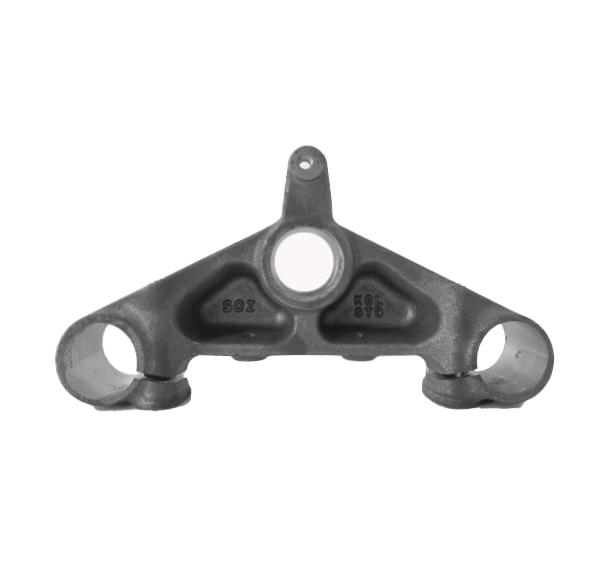

Stem Bracket

- Identify presence of holes

- Check for OCR

- Check for the presence of chamfer on the metal product

Clutch Plate

- Identify the rivet missing from the part

- Identify the rivet damage

- Track the pad damage

- Track the pin damage

- Identify the wrong assembly

Cylinder Block

- Detects dents and damages

- Recognizes chips

- Captures and verifies OCR readings

- Detects excess Loctite

- Identifies Foreign Object Debris (FOD)

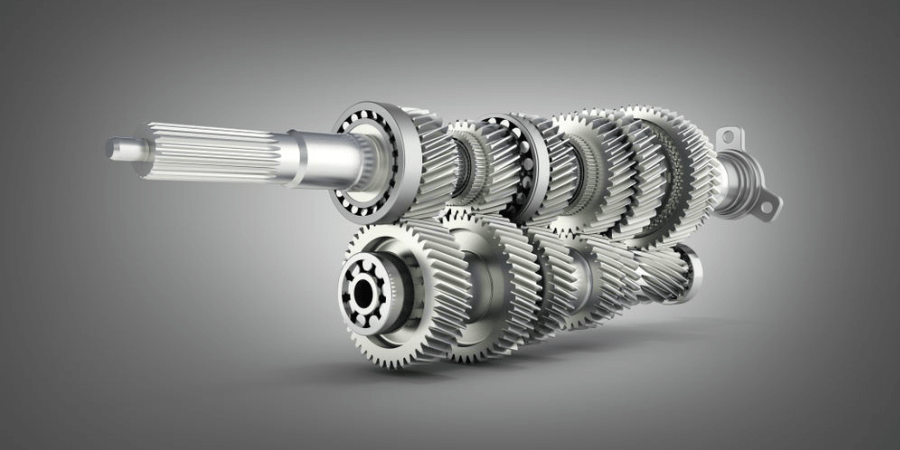

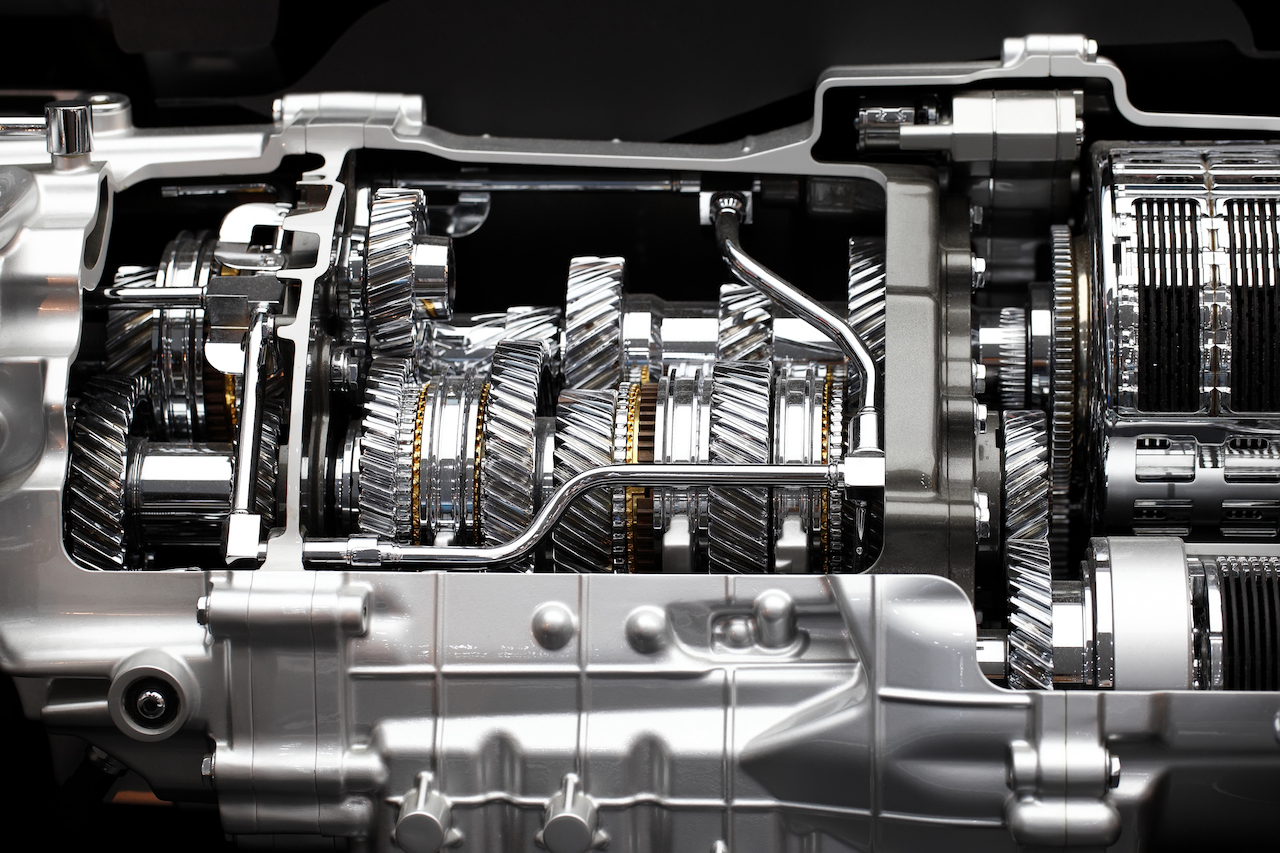

Transmission Gears

- Detects rust formation

- Identifies dents

- Recognizes dirt

- Inspects for full, partial, or zero grinding

- Detects incorrect welding

Cylinder Head

- Detects scratches, dent marks, and thread damage

- Identifies chips in the oil gallery hole

- Recognizes burrs at the injector bore intersection

- Detects foreign particles

Input Shaft

- Identifies shaft variants

- Detects notches

- Verifies proper assembly sequence

- Identifies rust and burrs

- Detects chip-off

Front/Back Side Door

- Check for proper pin placement

- Detect the presence of white papers

- Inspect twitter markings

- Verify hand rest installation

- Ensure red light functionality

Diesel Injector Needle

- Detects grinding defects

- Identifies delamination

- Recognizes grinding marks

- Detects tip damage

- Identifies scratches

- Check for droplets

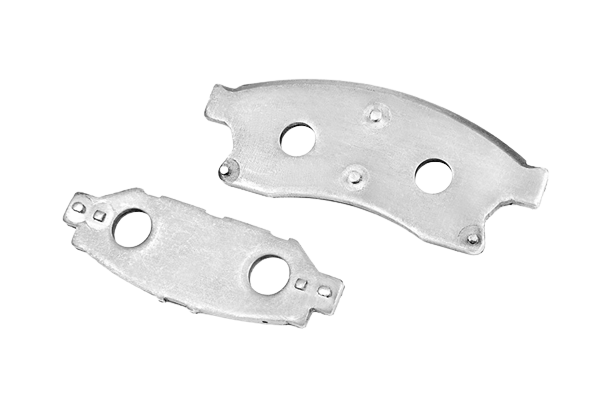

Brake Backplate

- Detect double punch marks

- Identify excess material

- Inspect for improper coating

- Recognize scratches

- Detect dents

- Identify cracks

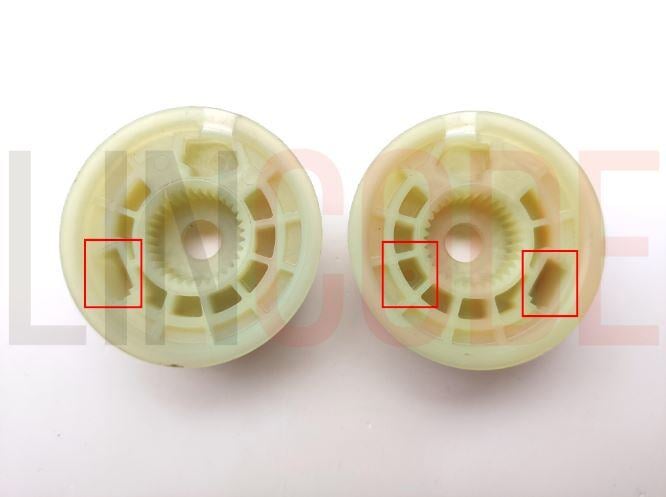

Window Rollers

- Classify parts into LH and RH

- Detect surface roughness

- Identify damages

- Recognize flash

- Detect discoloration

Car Bumper

- Detect surface defects

- Identify shape deformations

- Verify the presence and absence of clips, screws, rivets, nut springs, sensors etc

- Inspect for aesthetic defects

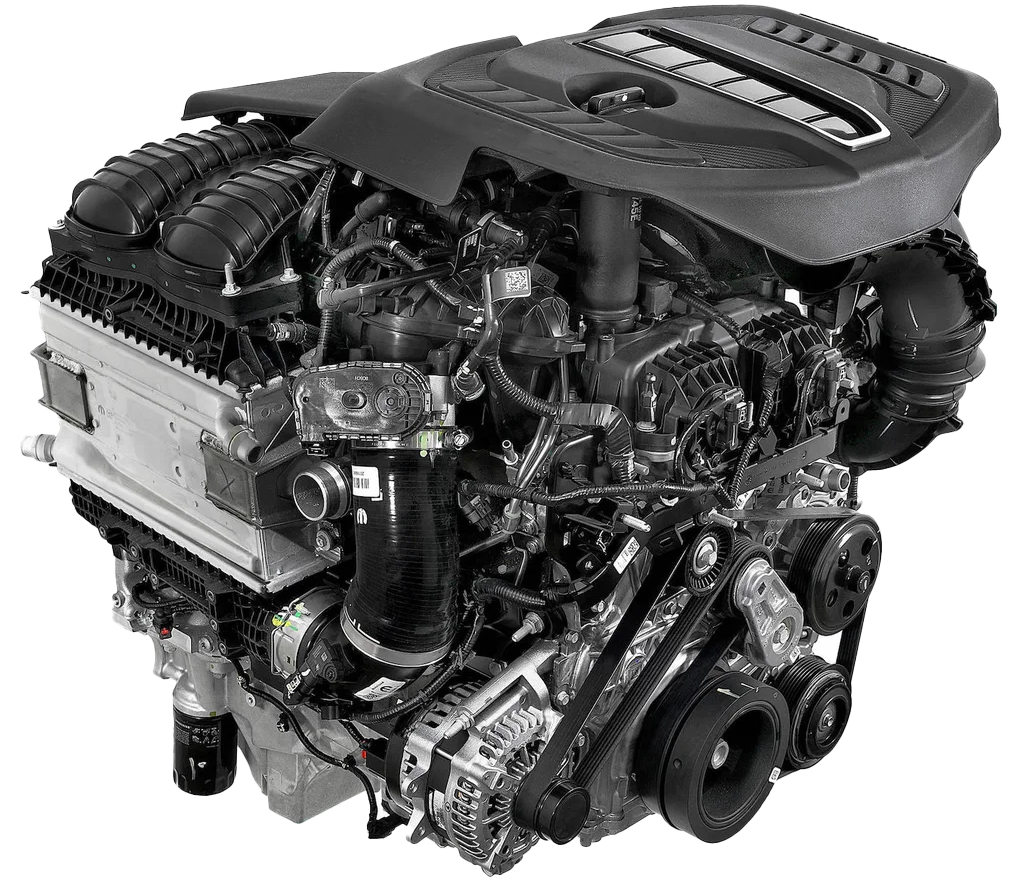

Engine

- Verify assembly accuracy

- Check for the presence and absence of child parts and features

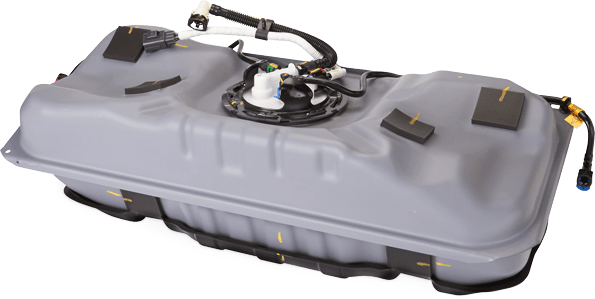

Fuel Tank

- Detect holes

- Identify dents

- Recognize black spots

- Detect rust formation

- Verify OCR readability

- Identify damages

Engine Valve

- Detect coating loss

- Identify surface roughness

- Recognize surface defects

- Check for dimensional errors

Gearbox

- Identify plastic deformation

- Detect abrasion

- Recognize cavitation

- Inspect for cracks

Differential

- Detect porosity

- Identify microcracking

- Identify microcracking

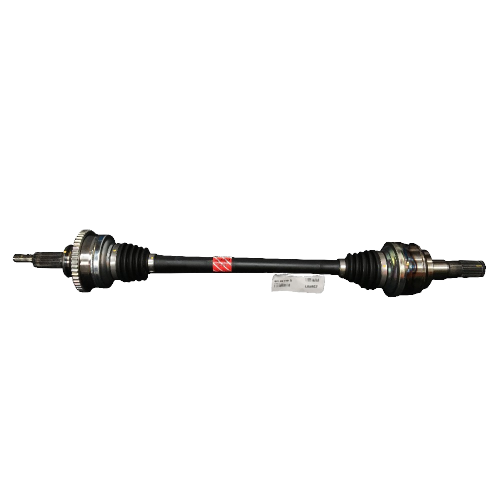

Drive Shaft

- Identify cracks in the rubber bearing

- Detect pipe deflection

- Check for slotted joint backlash

Transfer Case

- Identify dents

- Detect cracks

- Recognize porosity

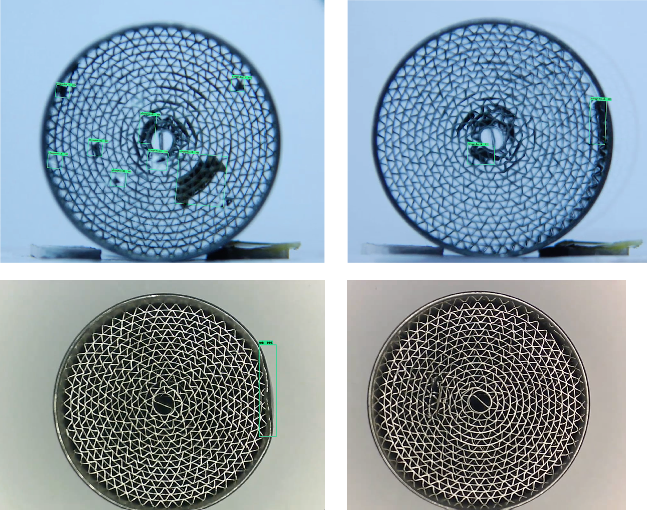

Catalyst Inspection

- 360 degrees inspection

- Detect Plugged cells

- Identify surface defects like dents, bends, coating defects

Connecting Rod Inspection

- Inspect for bolt plan burrs and burr in bush

- Detect crack marks and chip offs

- Identifying chamfer presence and absence

- Capturing the Needle print OCR

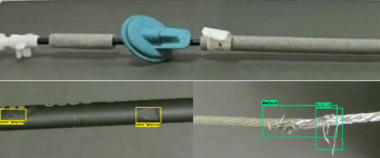

Wiring Harness

- Identify rubber surface defects like chip off, dents and breakage

- Detect surface defects on child parts

- Detect metal breakages

Turbo Charger (Housing components)

- Identify presence and absence of holes and chamfer

- Detect surface defects like dents and scratches

- Classify part accurately

Cockpit or Dashboard PDI

- Presence of parts as per variant

- Identifying Surface defects like scratch, crease, wrinkles, glue presence and more

- Detecting Stitching and paint defects

Paint inspection

- Identifying surface defects like scratches, pinholes

- Detect Dirt and rate orange peel

- Detect paint runs and sags

Weld inspection

- Identifying porosity and burn through

- Detect spatter and undercut

- Track absence of welds

Sealant Inspection for Door and Hood

- Detect excessive or missing sealant

- Verify mastic count

- Ensure gap consistency of hemming and mastic sealant

Body/ Stud inspection

- Detect surface detects like dents, cracks

- Verify stud counts and detect missing studs

- Validate for stud alignment

Deploy LIVIS via cloud or on-prem.

- LIVIS Cloud Platform. Web application to access LIVIS Platform on the cloud. Ideal for customers who prioritize global access, remote support, hassle-free updates, and deployment flexibility.

- LIVIS On-Prem Platform. Localized deployment of LIVIS Platform on premise at customer facilities. Ideal for customers with strict regulatory or data residence requirements, limited or unreliable internet access, or who require greater control over data infrastructure.

Third-Party Integrations

LIVIS seamlessly integrates with most industrial systems and processes, including those shown below.

Frequently Asked Questions

LIVIS Platform is Lincode’s Al model training and inspection workstation management platform. This is where factory workers train AI models for deployment, manage their LIVIS workstations company-wide, and access advanced features for factory automation. LIVIS Edge+ is the application that provides real-time analysis of quality inspections and generates inspection results directly at the edge. Both LIVIS Platform and LIVIS Edge+ are required to deploy a Lincode AI inspection workstation.

- Higher Detection Accuracy. Lincode’s advanced AI Inspectors can better distinguish between true defects and harmless variations, minimizing manual rechecks and quality escapes.

- Faster Setup and Adaptability. LIVIS learns and adapts to new parts and inspection parameters, enabling faster deployments and simplifying adjustments when production changes occur.

- Minimal Operator Training. An intuitive, user-friendly interface helps operators onboard faster with less technical know-how, encouraging widespread factory adoption.

- Scalable and Easily Integrable. LIVIS makes it easy to replicate AI Inspectors across similar production lines for faster expansion and connect effortlessly with cameras, robots, PLCs, and MES/ERP systems.

- Actionable Insights with Analytics. Leveraging real-time dashboards, defects trends, and root cause insights, LIVIS supports continuous improvement, predictive maintenance, and better decision making.

It depends. In some cases, the subscription model enables manufacturers to get the most value out of our products. With Lincode, you can deploy an inspection workstation for one particular use case, pay for certain features as you use them, and later redeploy that workstation for other inspection applications as many times as you like for as long as you keep your subscription active. But we understand that some clients prefer to allocate the full project budget up front and treat the cost as a capital expenditure. In such cases, we offer a perpetual license to use LIVIS in a one-time cost model, with a modest annual maintenance contract for clients who wish to receive ongoing support and product updates.

Both. LIVIS has an intuitive, no-code, Graphical User Interface (GUI) that is easy to use and does not require any specialized computer programming experience. LIVIS makes it easy to train AI models on new parts and defects, resulting in a fast adoption curve for both engineers and machine operators.

You own your data. While the LIVIS software and AI models are the intellectual property of Lincode, any data input into LIVIS (such as images used for inspection) belong to the client. Similarly, any output data generated through the inspection process (including inspection results and analytics) also belong to the client. Additionally, Lincode does not use client data to improve its AI models for any other customers without client consent.

It depends. All LIVIS Edge+ deployments are on-prem, meaning inspection data is stored at the client’s factory. LIVIS Platform may be accessed on-prem or via the cloud. For the LIVIS On-Prem Platform, all data is stored at the client’s factory. For the LIVIS Cloud Platform, all data is stored on the LIVIS cloud, which may be hosted by a third party. LIVIS and its third-party cloud hosting providers maintain industry standard data security protocols and are SOC 2 certified.

The LIVIS Cloud Platform is a web application to access the LIVIS Platform on the cloud. It is ideal for customers who prioritize global access, advanced features, hassle-free updates, enhanced security (SOC 2 certified), remote support, and deployment flexibility. The LIVIS On-Prem Platform is a localized deployment of the LIVIS Platform on premise at customer facilities. It is ideal for customers with strict regulatory or data residence requirements, limited or unreliable internet access, or who require greater control over data infrastructure.

Lincode takes data security very seriously. Lincode follows industry-standard data protection protocols and is SOC 2 certified. That means that Lincode applies robust data security protocols to its services and all customer data. Our latest Soc 2 Type 2 report is available to clients subject to the terms of your Lincode plan.

LIVIS is hardware agnostic and fully compatible with cameras that adhere to open-standard interfaces like GigE Vision and USB3 Vision. This includes major manufacturers such as Baumer, Basler, and Lucid, among others. For new deployments, integrating these cameras with LIVIS typically takes just a few minutes.

In contrast, some camera brands, such as Cognex, Keyence, and Omron, utilize proprietary ecosystems that often require specific software licenses or keys. LIVIS can still work with these systems by leveraging FTP to access image data that would otherwise be inaccessible.

For scenarios where direct camera integration is not feasible, the LIVIS Platform can analyze images through a file-sharing system. This includes common platforms like SharePoint, NAS Drives, OneDrive, and AWS S3 buckets. With this approach, existing cameras are programmed to save images to a designated shared folder, from which LIVIS can retrieve them for analysis.

This flexibility makes LIVIS a cost-effective solution. Organizations can reuse compatible cameras to protect prior investments or opt for industry-standard cameras to streamline procurement costs and minimize replacement lead times.

Typically, an industrial computer with a 2TB Hard Disk, 24GB memory, and A4000 GPU with 16GB of memory is a good starting point, with the understanding that each system is dependent on the particular deployment (e.g., number of cameras connected, simultaneous inspections running, and required cycle time). While an A4000 GPU has enough memory to process real-time inference results for most applications, some processes need to capture multiple images per inspection, which would require a higher-end GPU with a faster processor and more compute power. Lincode engineers can advise as to specifications appropriate in specific applications.

The LIVIS platform can analyze 2D images from any camera that complies with JPEG (JPG), PNG, or BMP industry standards. A minimum image size of 640 x 480 is recommended; however, the required image size will depend on the parameters of the particular elements to be inspected. Typically, we require 12 pixels to identify a particular defect. Based on this requirement, the camera system may vary based on the number of megapixels (MP), lens / focal length, and distance between the component and the camera.

Yes. Lincode offers the LIVIS mobile application as an Android app (Apple iOS under development) to enable engineers and machine operators to tackle new problems in production environments where handheld devices are desirable. Without the constraints of a fixed camera station, workers can use a smartphone or tablet to identify defects in parts that are not accessible with an industrial camera. Common LIVIS Mobile applications include foreign object detection (FOD), part presence & absence, and a host of defects (e.g., dents, scratches, cracks, etc.).

There is no technical limit to the number of features or defects that can be defined or assessed per part using LIVIS. However, the complexity of the inspection, involving a larger number of features or defects, will require more computational resources and storage. This will be reflected in the specific proposal or pricing.

Unlike most AI-based systems that require a large amount of data, LIVIS typically needs 30-50 samples per defect to develop a model. To fine-tune the model, a mix of images of good and bad parts may be added, and the system can continue to learn while in production.

Unlike other AI systems that require weeks or months to train, with LIVIS Initial training can be completed in a few hours and fine-tuning can take several days, depending on the complexity of the process or application. Total training time is proportional to the number of images and assumes a mix of good and bad parts.

LIVIS utilizes a combination of supervised and semi-supervised learning techniques to train its AI models. This enables the system to learn from both labeled and unlabeled data, allowing it to detect defects and anomalies with high accuracy. LIVIS’s patent-pending Evaluate and Train feature ensures continuous learning and enhances accuracy over time. LIVIS supports anomaly, classification, object detection, and segmentation models natively. We have also developed controls to use these models in combinations to create more complex AI vision pipelines. We also use anomaly detection and other unsupervised learning models to support data creation for more robust supervised learning algorithms.

LIVIS is designed to continuously learn and adapt. When the system encounters a new or rare defect type that has not been specifically trained, it flags this anomaly for an operator to review. The operator can then provide feedback with a single-click mechanism that teaches LIVIS how to handle new types of defects. This feedback loop allows LIVIS to learn and improve over time, enhancing its ability to identify and classify a wider range of defects.

LIVIS is capable of detecting defects with an accuracy rate far exceeding 99.99%, a significant improvement over traditional machine vision and manual inspection methods. The specific accuracy rate varies depending on the size of the training set and variance of defects in a production sample, but historically LIVIS provides a statistically significant increase in accuracy over previous inspection methods. Moreover, after initial training is complete, LIVIS continues to learn and is able to identify defects with subtle nuanced variations over time.

The inspection cycle time is the total time taken by the automation to process an image, make a decision, and trigger a response. This includes the time taken to capture the image, transfer it to the processing system, process the image, make a decision, and send a signal to the hardware to initiate the next action. Cycle time varies based on hardware, software, and network speed and latency. The LIVIS inference time typically operates at 50-150 ms, balancing performance and cost. For high-speed applications like Fast Moving Consumer Goods (FMCG), we are able to achieve inference times below 50 ms. In most applications, the LIVIS inference time does not pose an impediment to overall cycle time of an inspection station.

The distance of the camera is not a limiting factor as long as the camera itself has a high enough resolution to capture the detail necessary to provide a clear image. More importantly, any sides of the part to be inspected must be visible to the camera. Many factories use multiple cameras or automation processes to pass along parts in production. Ultimately, a suitable camera and lens is crucial to ensure that the required pixel density is achieved for detecting the minimum defect size.

Theoretically, there is no strict minimum or maximum size limit for detecting a defect. However, practical considerations such as camera resolution and image clarity influence the minimum detectable size. In general, a minimum size of around 100 microns is recommended for 2D inspections.

Once LIVIS is trained on one line, it can rapidly adapt to new lines with minimal additional data and training time. Our platform utilizes advanced techniques, such as transfer learning, to expedite the setup of new production lines. Unlike traditional machine vision systems that utilize single model training per camera, LIVIS can deploy AI training models across multiple cameras and production lines.

LIVIS supports a wide range of PLC protocols, including Modbus, Profibus, Profinet, TCP and SLMP to integrate with industrial robots, work cells and other automation systems. The specific protocol used will depend on the PLC manufacturer and the integration requirements of the customer’s system. LIVIS is versatile and hardware agnostic, supporting IP, Webcam, GigE, and USB cameras. The LIVIS no-code platform and library of APIs simplifies integration with modern automation systems.

LIVIS offers a comprehensive suite of analytics and reporting tools designed to provide valuable insights into manufacturing processes. We are committed to providing industry-standard metrics and visualizations to help optimize factory operations. Some of the key analytics and reporting capabilities include:

- Precision and Recall: Evaluate the accuracy and completeness of defect detection.

- Customizable Dashboards: Visualize key performance indicators (KPIs) and trends.

- Detailed Reports: Gain deep insights into specific defects, production lines, and time periods.

LIVIS provides APIs that can be integrated with various manufacturing systems, including CMS, SAP, MES, and ERP to publish inspection results. This integration enables seamless data flow and improves overall operational efficiency. These results can be visualized on dashboards, exported to reports, or used to trigger automated actions.

-1.webp?width=327&height=316&name=download%20(97)-1.webp)