Make Your Computer Vision System

Smarter, Faster, Simpler

Quality inspection system for manufacturing using computer vision and AI.

Detect defects, verify assemblies, and ensure data traceability.

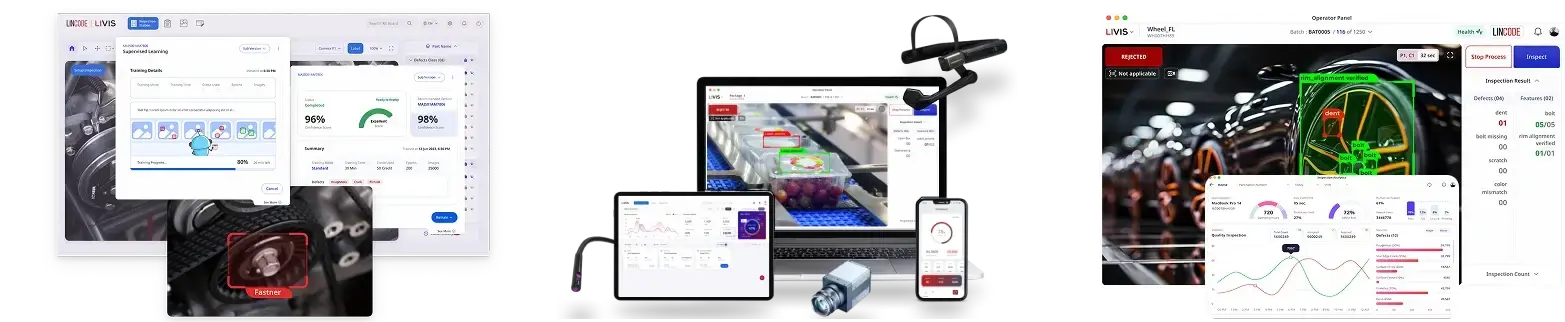

Meet LIVIS: The AI Visual Inspection Suite Built for Modern Manufacturing

LIVIS is more than an automated inspection system—it’s your competitive edge. By combining deep learning and computer vision, it helps you catch defects faster, reduce inspection errors, and maximize uptime.

The LIVIS Suite includes:

.png?width=56&height=56&name=Part%20Recipe%20(1).png)

LIVIS Platform

A no-code inspection platform that enables your team to train and deploy AI models for new parts, defects, and production lines.

.png?width=56&height=56&name=Part%20Recipe%20(1).png)

LIVIS Edge+

Conducts real-time inspections and improves accuracy and performance beyond traditional inspection systems!

.png?width=56&height=56&name=Part%20Recipe%20(1).png)

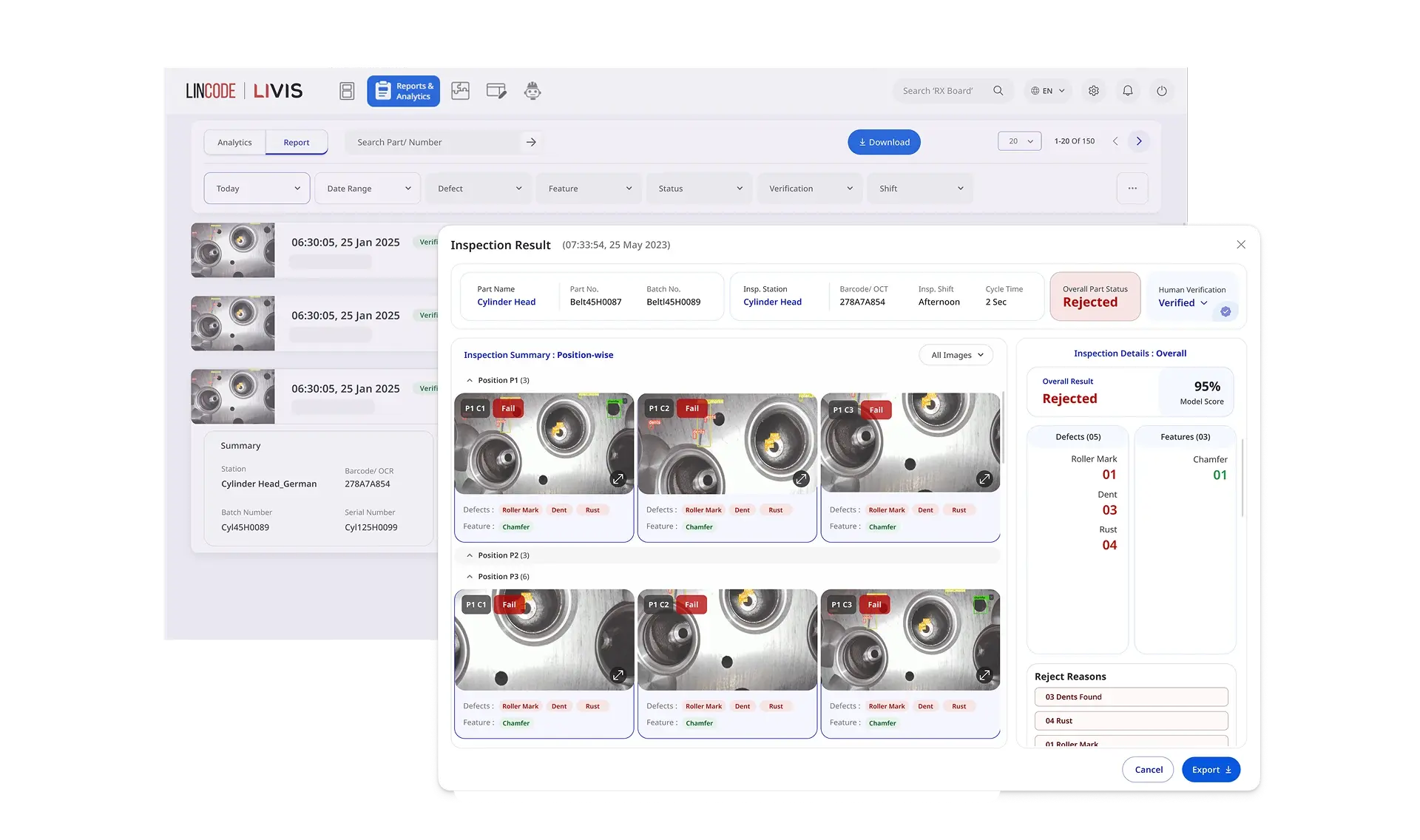

LIVIS Insights

Delivers detailed analytics, defect tracking, root cause analysis, and predictive maintenance.

Why Global Manufacturers Trust LIVIS

AI Inspection: Advanced defect detection that evolves with your production needs.

Automatic Inspection System: Real-time feedback for immediate quality control.

No-Code Inspection Software: Quick deployment with no technical barriers.

Flexible Integration: Supports edge, cloud, and on-premise setups.

Seamless Compatibility: Works with your existing camera systems and manufacturing lines.

Inspections Completed

Deployments

Datasets Processed

Countries Served

Trusted by Experts, Powered for Modern Manufacturing

.png?width=79&height=66&name=Vector%20(20).png)

As pioneers in visual quality inspection using AI, Lincode has helped us solve many challenges in BIW automation lines where traditional vision systems fail to support our applications. The Lincode team is highly flexible to our requirements and has extended their services beyond the initial specifications to help solve the problems on-site.”

Rajsekhar Jaypal

AVP, Welding Systems, DiFACTO Robotics and Automation

It's Time to Transform Your Quality Control!

Discover how Lincode’s optical inspection system can cut costs, reduce errors, and help you deliver higher-quality products faster.